Compressor Plant

This report we tour the compressor building at the historic Turner Valley Gas Plant, just south of Calgary. Inside this long cavernous structure is a bank of ancient engines with integral compressors, the size of which are are hard to describe. They’re big, really big…let’s call them behemoths! These were used to pump gaseous petroleum products about the facility and to maintain line pressure in the pipeline leading from it. The plant has long since shut down and the building is now eerily quiet.

The entire complex, the compressor building and these engines included, can all be visited by the general public when accompanied by interpretive guide (summers only). This day we special permission to explore and photograph everything (heck, we got to run amok), outside the normal operating season.

The Turner Valley Gas Plant dates back to the 1920s, although most of what’s seen here is from the 1930s or later. The compressor station dates from the period 1938-49. When the Turner Valley petroleum field was first exploited, starting in the 1910s, the natural pressure of the gas emerging from the ground was sufficient to propel it about. As the field matured, that pressure dropped and so this machinery was brought in to take over that job.

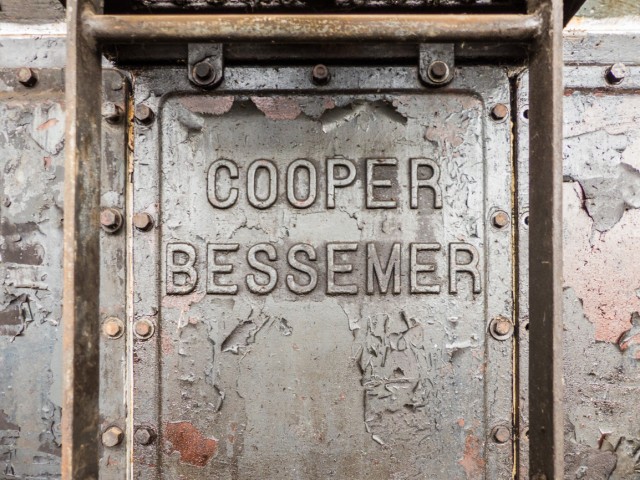

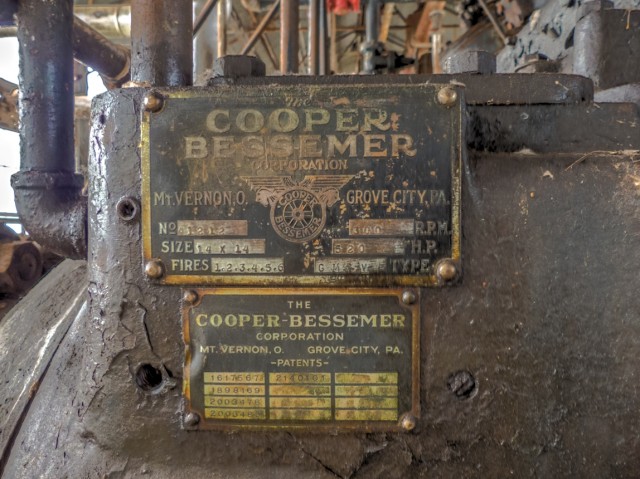

There are ten engine/compressor combos in the building, each a Cooper Bessemer GMV series. That firm was a big player in the gas compression field and this model was one of their most popular. They were made by the thousands for use in gas plants, natural gas pumping stations, oil refineries, chemical factories and so on. The first ones were built in the late 1930s and the model remained in production, in various upgraded forms, for fifty plus years! The ones at this plant date from the late 1930s and into the 1940s and are six cylinder models. They were offered in sizes from four to twelve cylinders in a V configuration.

While Cooper Bessemer had a factory in Canada, that I understand was set up make this series of engine, all the maker’s plates we found (not every engine/compressor had one) only mention the US plants. Cooper Bessemer was later named Cooper Industries and stopped making integral compressors in 1980s. Today they are called Cameron International.

Each engine drove a pair of reciprocating pistons, contained within a compressor cylinder, which then feed pressure into the line. The size of these and everything else associated with the machine, is on a huge scale. A complex lubrication system kept everything running smoothly.

The engines operated off fuel produced at the plant. Exactly how they were cooled was not made clear and no radiators were seen. Each engine operated at 300rpm and produced 520 horsepower. The din of these when at power mush have been earth shaking and ear splitting. A huge muffler off each exhausts to the roof.

Depending on demand, not every engine/compressor combo would be in operation at any one time. Once running however, they were expected to do so 24/7 at full power, for extended periods with very little attention. These beasts were clearly overbuilt so I doubt that was a problem.

By the time the Turner Valley Gas Plant closed in the mid-1980s some of these machines would have been on the job for well over forty years. It was was a virtual operating museum by that time. Even, so it’s clear even today, that these engines were well maintained, right to the end. I guess they had to be.

One thing I noticed when entering the building is how it’s almost time capsule like in nature. Everything looks like it’s ready to be fired up at a moment’s notice.

Next door to the compressor building is the scrubbing plant which removed sulphur from the gas. It and other parts of the complex will be seen in another report which we’re hoping to publish soon.

The Turner Valley oil and gas field has been producing for just over a hundred years and was the birthplace of the Alberta petroleum industry. Yup, it all started here. And it continues today. Most output, as it’s always been, is in condensate form which is complex cocktail of gases and lighter fluids all mixed together.

Thanks to the Foothills Camera Club who allowed us to tag along with their group on a special free-run tour of the complex, and to the Turner Valley Gas Plant organization itself who hosted the event. A special thanks to James Tworow, who brought it all together for us.

More stuff you’ll like…

Horseshoe Dam.

A day with the Battle River Railway.

Diplomat Mine site.

If you wish more information on what you’ve seen here, by all means contact us!

Date: March, 2015.

Location: Turner Valley, AB.

Article sources: Book: History of Turner Valley Oilfields, Plant guides, Cooper Bessemer company papers.

Tours of the plant can be arranged, but outside that it’s not publicly accessible.

Cooper Bessemer GMVs at the Turner Valley gas plant.

There is a bank of ten in the building.

Cooper Bessemer was big in the gas compressor field.

The power cylinders are absolutely huge.

The lubrication system.

RPM: 300. HP: 520.

These compressors were installed in the 30s/40s and last used in the 80s.

The din when running must have been ear splitting.

Each engine powered a pair of these compressor cylinders.

Gas lines leading into the building. Horton Spheres in back.

These machines are huge!

Looking out at the scrubbing plant.

The compressor building.

thank you for sharing, Reminds me of Hagood Gas Plant in Rangely

Looked online and if I found the right place, yes, it’s very similar! Very cool. Your profile pic suggests your into this kind of stuff. Come back often and comment when you can which helps us get seen by a wider audience.

I wrote a detailed history of this operation in Abandoned Alberta. If you’d like to see it let me know.

Please do send it. The contact page will tell you where.

Cooper-Bessemer was quite well-known at one time for their big diesel engines used in ships and power generation. Cooper-Bessemer engines were also widely used by the Page Engineering Company in their walking draglines.

Their engines could be found in locomotives as well.

This begs to be shot in B&W…

Well…I did one that way!

I’ve gotta get out down there this summer. What an amazing place!

If you like old machinery, you’ll love the place.