Greenhill Mine, an incomplete tour

The Greenhill Mine site is a slice of history, a long abandoned but nearly complete coal mine and surface plant from the past. An operating museum by the time it closed in the late 1950s, it’s as though time just stopped here. A designated historical site, the elements and vandals have taken their toll and if not stabilized soon the site is destined to deteriorate even further. And that would be a loss.

The complex has many buildings and features, including a sealed mine portal, a lamp and wash house, compressor buildings complete with machinery, and other structures. In this visit we’ll explore some of the site, but by no means is this a complete tour. There are many bits that we’ll shoot on subsequent visits, including the tipple (fenced in) at the south side of the property, fans and hoist houses further up the ridge. This was a large operation and it will take many visits to explore.

One of the first things you see on entering the Greenhill Mine site is the Quonset shed that covers the mine tracks as they exit the portal. I guess these were to keep the mine trains out of bad weather. Inside there are old mine tracks and at one side, a number of core trays. These are marked “Grassy Mountain Mine” which means this plant was processing coal from that aforementioned mine too. Both were owned by the same company, West Canadian Collieries, so this makes sense.

The concrete portal is sealed and the date 1944 can be seen stamped on top. This and a side portal have sulphur springs coming from them and boy do they stink!

The railway here, like all underground mine railways, is of narrow gauge construction. Meaning the rails are closer together and the trains smaller than typical. So far this author has only found records of compressed air locomotives being used in the mine, but it’s possible other types were used as well. This could mean battery locomotives, trolley locomotives or even horses (likely only in the early days). This is only conjecture on my part based upon what was common practice of the day.

On exiting the mine the coal cars were taken to the the tipple and dumped and the coal cleaned and sorted (clean coal, that’s funny). From there it was loaded on to waiting rail cars or trucks.

To the east of the train shed are some old coal cars, stacked up nicely and all missing their wheels. Nearby are the remains of a drag chain conveyor for moving coal about the plant. This form of carrier is interesting and it uses paddles to push the coal around, instead of a belt to move it.

Just beside that are some collapsed or burnt buildings with various bits of odd machinery in and around them. They must have been repair and machine sheds. A small crusher was found in one shed and it would have been used for sample testing.

To the west of the train shed are a couple more burnt or collapsed buildings. One must have been the explosives shed and had a machine in it was marked “Cardox cartridge charging plant.” I assume this has to do with explosives and I invite correction if I am wrong.

Further west the lamp house is next. A very important building, it’s here they kept track of who was in the mine. Every underground worker was issued a lamp and all of it was careful documented (by way of unique employee tags). If someone did not return from their shift it would be easy to see they were missing and a team would be sent in to look for them.

Across from the lamp house is the wash house. This is where the miners cleaned up after a hard days work (coal mining is incredibly dirty) and where they changed into their regular clothes. At some point they started using this building as a core shed and the whole place was wall to wall and floor to roof with core samples. The paint on the ceiling has been breaking down and oozing, making these neat mini-stalactite formations.

Up from the wash house is an old boiler. Marked the “Jenckes Machine Co, Sherbrooke Que”, it’s dated 1903. The Jenckes company was a large concern supplying all manner of mining and industrial machinery across Canada. These boilers provided hot water to the wash house in addition to other parts of the plant. I assume it was fired with coal. :>

Beside are some old tanks and vessels and beyond that, a compressor house. There are actually two compressor buildings but one is completely gone even though the machinery remains. In each, one central motor drives two compressors. These were made by the Sullivan company which still makes compressors to this day. See the article “Greenhill Mine then and now” to see two of the machines as they appeared in 1924 when newly installed. The company sure got good use of their equipment and these were obviously used right up until the time of the mines closing. Near the end this place must have been an operating museum.

These air compressors were essential to mining, and were used to drive air tools and machinery deep inside the workings. There would be a pipe with regularly spaced taps which workers could tie their air lines into. Like the underground railway the pipe would be extended as the mine face moved forward. These were not used to provide fresh air to the mine. Instead it was supplied by large fans placed at strategic intervals in and about the mine and they are not shown in this report.

West Canadian Collieries opened The Greenhill Mine in 1913 and this operation superseded some of the companies other mines which were closing at the time, like those at Lille further northeast of here. Operating all the way to 1957 or 1958 (depending on which source), this mine was a major producer and a mine map seen by this author shows how extensive the underground workings were. It operated on many levels and made Swiss cheese of the ridge they were mining.

As mentioned it’s also clear that the surface plant here processed coal from the nearby Grassy Mountain strip mine, This mine operated from the 1940s until it too closed in 1957 or 1958 (again depending on which source). Demand for coal by that time was quickly waning and by the late 1950s coal was NOT a good business to be in. West Canadian Collieries dissolved as a company in 1962. This company is sometimes refereed to as Western Canadian Collieries, perhaps in error. For simplicity’s sake we’ll consider these two names interchangeable.

The only other coal mining complex that matches this one for completeness is the Coleman Collieries operation in its namesake town a bit further west down the valley. It dates to the late 1970s / early 1980s and was the last coal plant and mine to operate in the pass.

We’ll return at some point to document the rest of the operation. It’s extensive as mentioned and requires more study. That sounds like fun!

I apologize for the blown out contrast on some of the pictures. Our camera was acting up I am afraid.

To see some other coal mining relics in the area, refer to these links…

Crowsnest River walk and Hillcrest-Mohawk Collieries plant.

Coleman Collieries plant and mine.

Tent Mountain was torn a new one.

If you wish more information on this place, by all means contact us!

Date: May 2012.

Location: Crowsnest Pass Alberta.

A small crusher for sample testing.

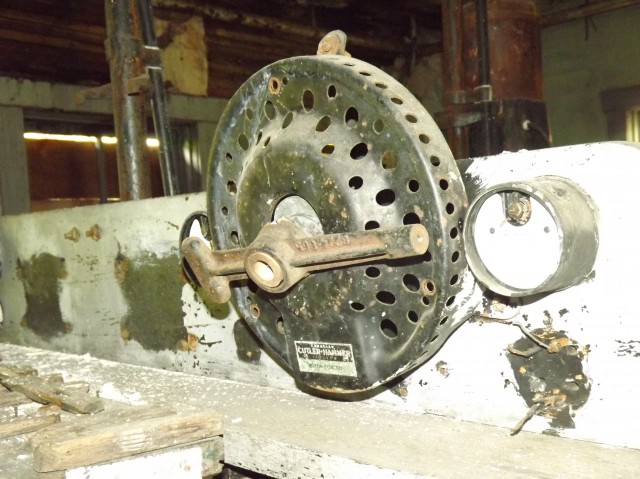

Some sort of hoist control.

I have no idea what it is!

Remains of a drag chain conveyor.

A row of rotting coal cars for use inside the mine.

The shed before the mine entry.

Tracks at the Greenhill Mine portal.

A sulphur spring (in the centre) flows from a collapsed opening.

Old machinery in a burnt out building.

The mine portal reads 1944.

A close up of the sulphur springs coming out of the hill.

Old drill cores in the portal shed.

“Cardox cartridge charging plant.”

Mine compressors, one set in a building and another not.

Sullivan compressors, a company that’s still around.

Each motor drives two compressors.

These compressors date from the 1920s or earlier (see the post for more info).

Old tanks nearby.

The lamp house.

There were a number of these inside the building but I have no idea what they do.

The lamp house was a very important building (read the post to find out why).

An old boiler with the date 1903.

The Greenhilll Mine compressor building.

The exterior of the lamp house.

The old wash house converted into a core shed.

My Grandad died in the 1949 mine collapse at the Greenhill Mine in Blairmore, AB. I would love to see this site someday but it isn’t open to the public and my age is becoming a factor.

Coal mining, the underground stuff in particular, was always such a dangerous occupation. Sad to hear it happened – must have devastated your family at the time. If you like we can go back in and make a photo album for you. Our society would happily do it no charge. Respond here if interested. We’re in a the area all the time. An associate looked through mine death records and found two names: Carter and Kwaitowski, both who perished on the same day in December 1949 in the Greenhill Mine.

Cardox heats liquid CO2, and converts it to a gas. Volume increases some 600 times, almost instantaneously, and generates pressures up to 40,000 psi. This breaks up the coal without the use of explosives, and given the nature of coal dust and the methane, is a safer way to “blast”. Taken from their website.

Ahhhh. That’s interesting. I’d heard about somewhere but it was never fully explained. Thanks, that makes sense.

I’m very interested in the history of the Greenhill Mine. My Grandfather was one of two miners killed in the cave in December 1949. I have received a partial article on this accident but not enough to really fill me in on the actual out come. My grandfathers name was Ben Carter and he is buried in the Blairmore cemetery.

I look forward to hearing your comments on this story and any light you can shed on it. My husband and I are planning a trip to the Pass this May.

Thanks Peggy

Hi Peggy,

I’ve heard of a few deaths in that mine over the years (no mine, it seems, was immune to that). Before commenting, I’d love to read what you have on that incident. Can you scan and email it?

If you ever need any research help, let me know.

Chris…

Just came across your interesting site! I love the Crowsnest area and just re-visited the Greenhill mine site which I thoroughly photographed in 2012. The two buildings (compressor etc) adjacent to the lamp building are now fenced. Kind of changes the look of the site. Other building remain accessible….. anyway for what it’s worth.

Thanks, Doug

Hmmm, I wonder why they would be fenced? Perhaps they are becoming too dangerous? Thanks for posting Doug.

How long has it been abandoned? It seems in pretty decent shape overall.

It’s been abandoned for over 50 years! It’s not in bad shape but vandals, the elements and time are taking their toll.

It’s like a museum, everything left in place when work stopped.

Yes, it’s just like that. Like they just up and left one day.